SPECIFICATION

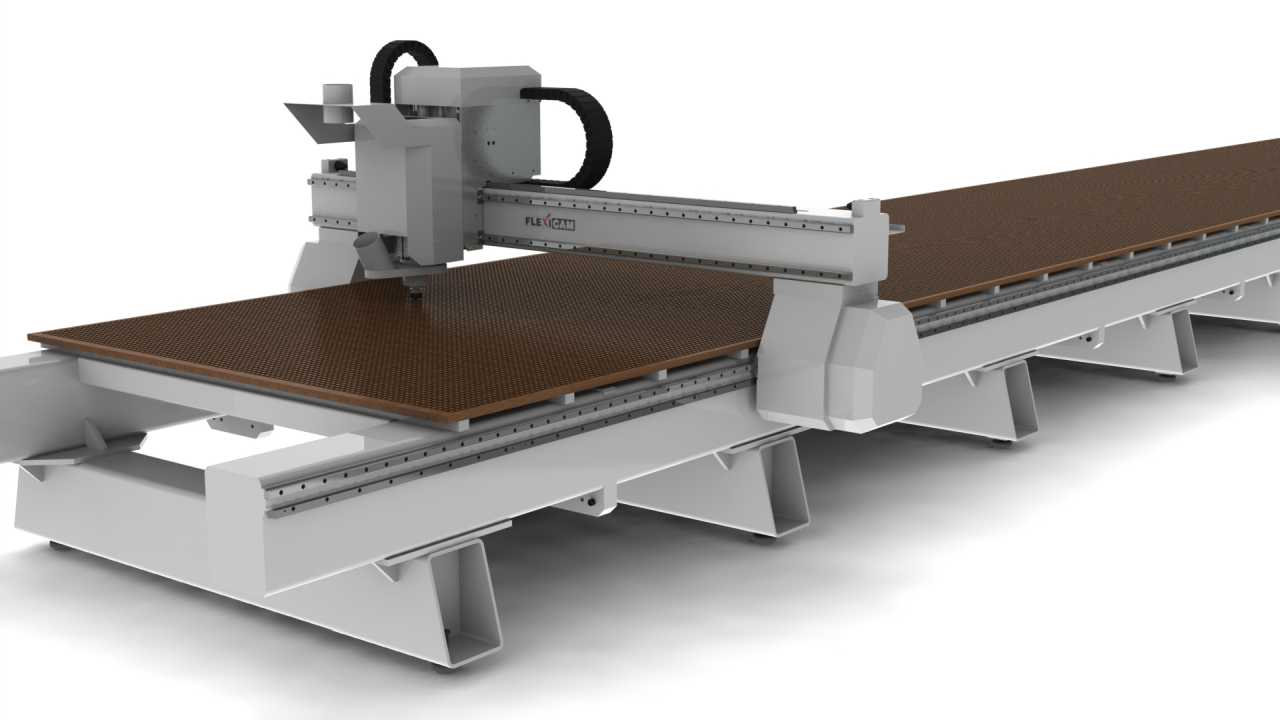

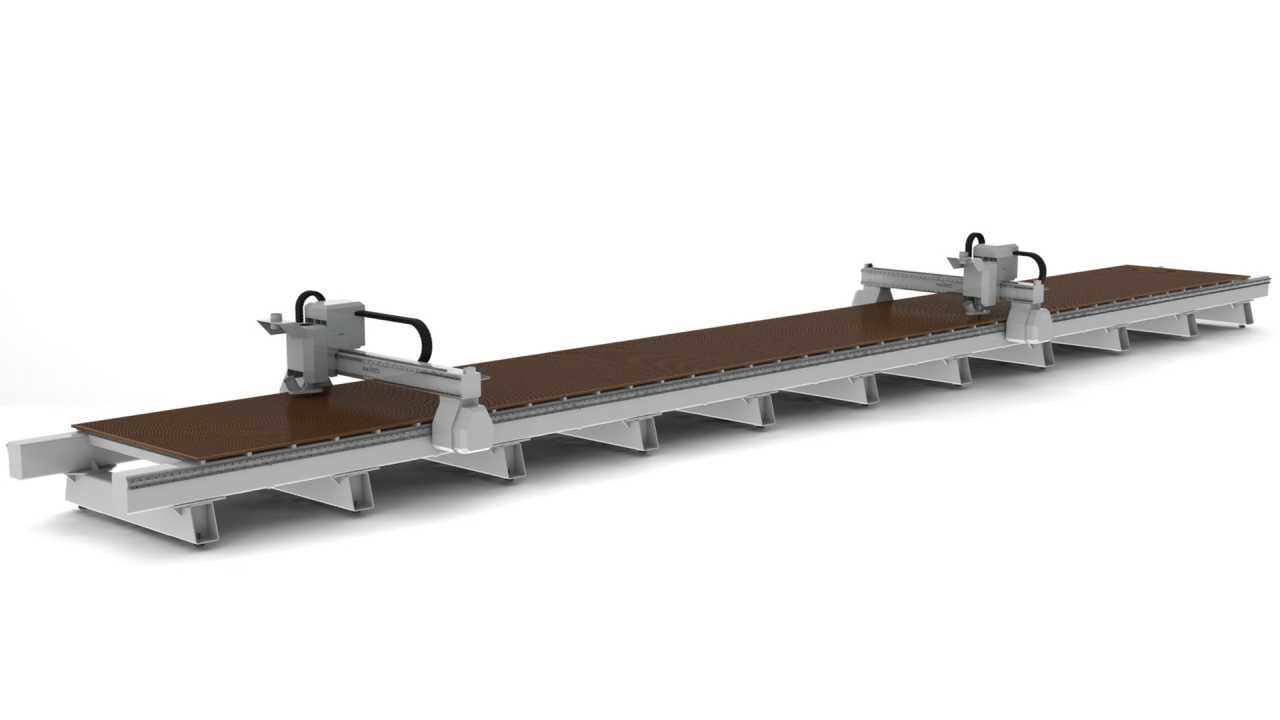

- Space-saving fixed table - moving gantry design for small machine footprint

- Single structure welded, stress relieved and machined all-steel baseframe, gantry and gantry feet

- Steel structures are reinforced with heavy ribs to resist flex and dampen vibrations

- Each machine design is efficiently optimized and validated by using Finite Element Analysis (FEA) to ensure quality, performance, and safety

- Open machine bed for easy loading and unloading by forklift or overhead crane

- High preload profiled linear bearings with cover strips on all axis

- Brushless digital A/C servo drives and motors on all axis

- Dual side drive and synchronised X-axis; no twist under load like applicable to a single center-mounted ballscrew or cantilevered design

- Helical rack and pinion drive system on X and Y axis

- High precision ballscrews on Z axis (anchored at both ends)

- Low-backlash planetary gear boxes

- Fully closed cable carriers prevent the cables from damage by chips and fine dust

- High quality, shielded cables for energy chains are a guarantee of reliability

- Z-axis clearance 200 m, optional 280 mm or 400 mm

- Z-axis travel 280 mm, optional 480 mm

- Maximum axis speed 100 m/min (1,000 mm/s) depending on controller, motors and drives

- Network connection via Ethernet (optional Wireless)

- Remote Administration via Internet

WORKAREAS

- 1,540 mm (XXL 15xx)

- 2,040 mm (XXL 20xx)

- 2,540 mm (XXL 25xx)

- 3,040 mm (XXL 30xx)

- 3,540 mm (XXL 35xx)

- 4,040 mm (XXL 40xx)

- 3,080 mm (XXL xx30)

- 4,080 mm (XXL xx40)

- 5,080 mm (XXL xx50)

- 6,080 mm (XXL xx60)

- 8,080 mm (XXL xx80)

- 10,080 mm (XXL xx100)

- 12,080 mm (XXL xx120) etc.

The available lengths starts at 3,080 mm and increases in 1,000 mm increments, e.g.