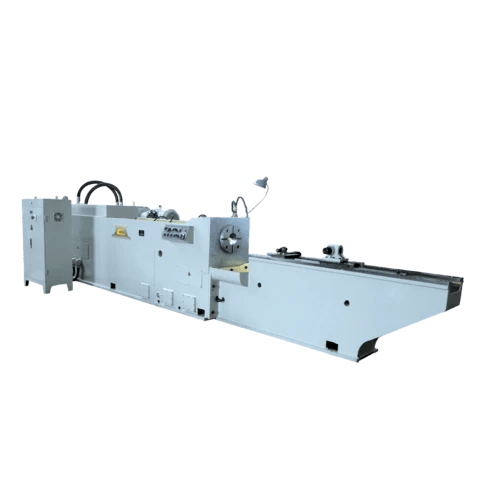

FEATURES

• Driven by hydraulic power, with variable speed

• High Pressure Chip Flushing System

• Automatic Cycling, Semi Automatic

• Cycling and Segmented Cycling available

•Centralised Lubrication

|

Model |

HBR10 |

HBR20 |

HBR40 |

HBR60 |

HBR80 |

|

Rated Pulling Force |

100kn |

200kn |

400kn |

600kn |

800kn |

|

Max.Stroke Length |

1250mm |

1600mm |

2000mm |

2000mm |

2000mm |

|

Length Range of Broaching Tool |

600-1300mm |

600-1650mm |

600-2050mm |

600-2050mm |

600-2050mm |

|

Hole Diameter of Worktable |

100mm |

130mm |

150mm |

250mm |

250mm |

|

Max. Outer Diameter of Workpiece |

570mm |

620mm |

640mm |

680mm |

680mm |

|

Working Speed |

2-11m/min |

1.5-11m/min |

1.5-7m/min |

1-6m/min |

1-4.2m/min |

|

Returning Speed |

14-25m/min |

7-20m/min |

12-20m/min |

5-14m/min |

5-12m/min |

|

Motor |

15kw(20.4hp) |

22kw(29.92hp) |

37kw(50.32hp) |

55kw(74.8hp) |

75kw(102hp) |

|

Verticality Of Center Line Of Broach Rear Hole on Tested Workpiece Against Base |

0.06/200mm |

0.06/200mm |

0.06/200mm |

0.06/200mm |

0.06/200mm |

|

Overall Dimensions |

5620x1720x 1350mm |

6830x1820x 1440mm |

8640x2055x 1375mm |

8460x3000x 1454mm |

8460x3000x 1454mm |

|

Net Weight |

4800kg |

5900kg |

10500kg |

12000kg |

12500kg |

STANDARD ACCESSORIES

• Tool Chuck

• Auxiliary Tool Chuck

• Faceplate

• Hydraulic Station

• Lubrication System

• Cooling Pump

• Chip-removal System

OPTIONAL ACCESSORIES

• Oil Cooler

• Air Spray Gun

• Broaching Tool

• Automatical Chip Conveyor (with chip trolley)